How is a baffle wall constructed?

A baffle wall will reinforce low-frequency energy and can provide as much a +6db of output without increasing the amplifier power. This increases efficiency and creates a better sounding system.

A baffle wall should be lined with thick absorptive material to suppress reflection as much as possible. Walls and ceilings should be constructed using multiple layers of plasterboard with each layer being completely installed before the next layer. So the ceiling then walls should be installed, followed by ceiling and walls again. This will create a lap joint in the corners rather than a butt joint which could provide a flanking path for soundwaves and negate or at least compromise your sound isolation. In between each layer absorptive compounds help to soak up the low-frequency energy. Once the ceiling and walls have been constructed, further architectural elements can be built such as your baffle wall, stages, soffits, or raised seating platforms.

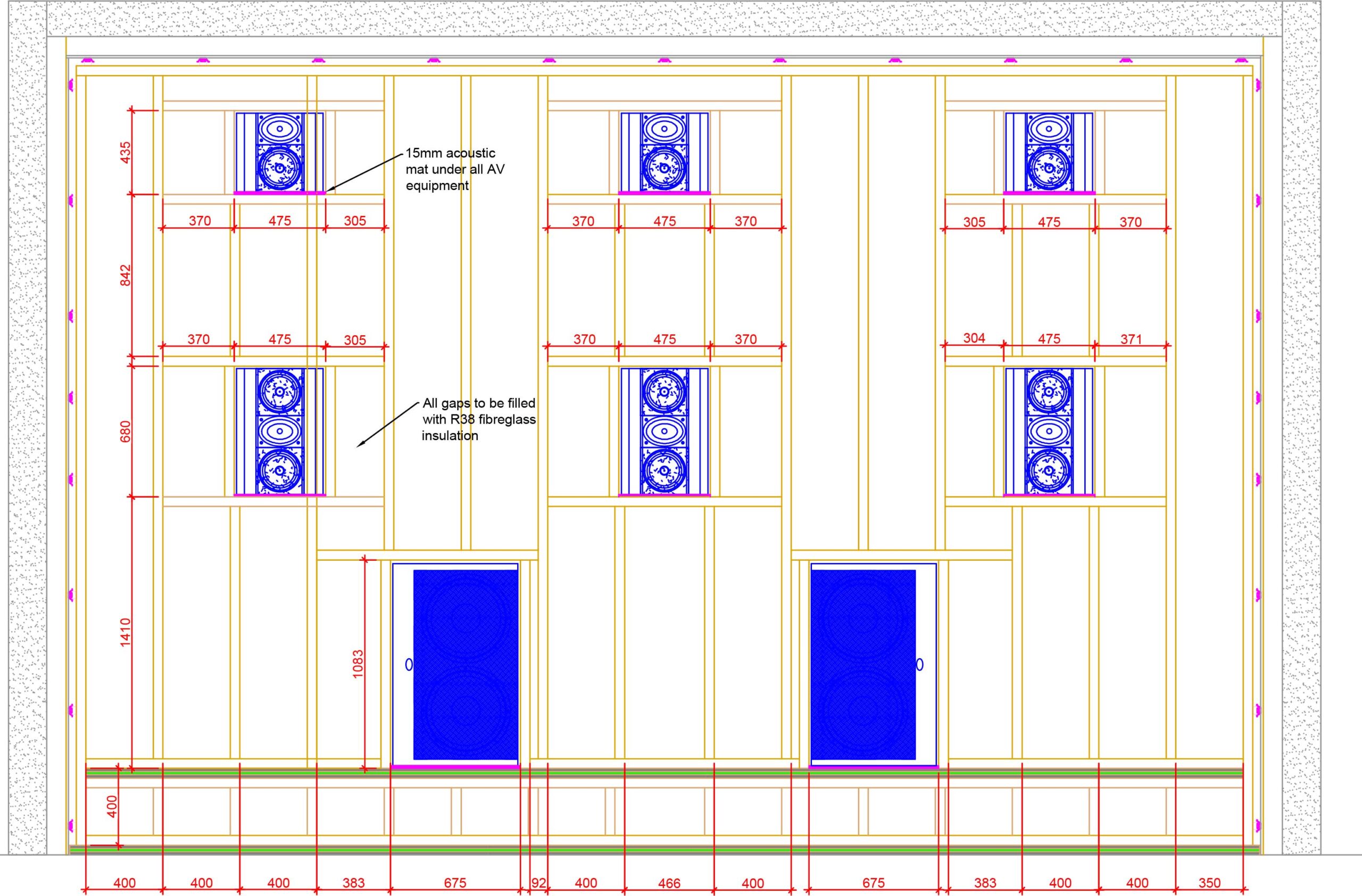

The baffle wall should be constructed leaving a void between the front end wall and the back face of the baffle wall. The distance between the front end wall and baffle wall will depend on the hardware being installed and should be noted on the cinema room design plans. The larger the gap between each surface, the greater the sound transmission loss.

Timber studs 44mm x 95mm (2”x4”) should be used to construct the frame with 400mm centres. Spaces should be filled with acoustic mineral wool insulation

The baffle wall surface is constructed using a layer of 12.5mm plasterboard fixed to the studwork followed by 9mm MDF and a further layer of 12.5mm plasterboard. Green Glue should be used between layers.